ROMCO 150

![]() 150 is a compact, high productivity Printing Machine that can be used in Letter Press Houses, DTP units, large Xerox (Photocopies) and Screen Printing Houses as well as small Enterprises. It is ideal for short-run jobs. Even novices with minimal training, can operate the machine with ease.

150 is a compact, high productivity Printing Machine that can be used in Letter Press Houses, DTP units, large Xerox (Photocopies) and Screen Printing Houses as well as small Enterprises. It is ideal for short-run jobs. Even novices with minimal training, can operate the machine with ease.

It can print using both Poly Master as well as Plate. All the bearings fitted in the machine are of standard brands. Body cover are powder coated, giving its elegant look.

Particulars |

Specifications |

Dimensions : |

66”L x 34”W x 57” |

Weight : |

700 Kg. |

Power Requirements : |

200-240 AC |

Maximum Paper Size : |

10.75”W x 15.0”L |

Minimum Paper Size : |

5”W x 7”L |

Maximum Image Area : |

10.25”W x 14.5”L |

Paper Weights : |

30-300 GSM |

Blanket Thickness : |

1.9 mm (4 Ply Rubber Blanket) |

Blanket Size : |

11.25” x 18.5” |

Plate Size : |

11” x 16.5” |

Gripper Margin on Paper : |

8 mm |

Gripper Margin Plate : |

1.25” |

Feeding System : |

Suction Feeding |

Ink Rollers : |

12 Ink Roller, Includes: 3 Oscillators, 2 Form Rollers |

Dampening Rollers : |

5 Rollers, Include: 1 Oscillators, 2 Form Rollers |

Printing Speed : |

1500-5000 IPH |

Main Drive Motor : |

1 HP Single Phase |

Compressor Pump Motor: |

1 HP Single Phase |

NOTE: Due to continuous development and product improvement, the company reserves the right to change/alter the specifications mentioned without prior notice. |

|

Key Features |

|

|

|

Features: |

|

|

Stream Feeding System Our Stream Feeder ensures safe & smooth paper / board feeding. |

|

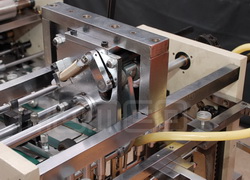

Chain Delivery Three separate gripper systems transfer the printed sheets into the delivery. The printed sheets are gently and evenly tested at all the speed. Chain Delivery has a unique function of automatically receding wheel away Paper Platform. |

|

Central Lubrication System The centralised lubrication system supplies sufficient amount of lubricant automatically in frequent intervals as specified in the timer to all functional points during the press operation preventing wear and tear of the machine. The required amount of oil is supplied to all exposed points by an oil pump. And another manually controlled lubrication system distributes the oil to further points, minimizing maintenance and increasing the service life of the machine. |

|

Adjustable Front Lay System Improved adjustable front lay for registration control on maximum speed. |

|

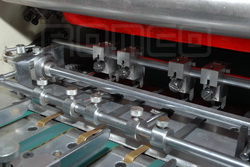

Cylinder Grippers The perfect design of cylinder gripper senses the rhythm of front lay & side lay. Hence the heart of sheer perfection of registration achieved at maximum speed and simple flexible system adjust to the various paper stocks. |

|

Dampening System Standard dampening design is made up by five rollers, with one vibrator roller. The vibrator (the water trough rollers and the water tank are made of stainless steel materials to ensure long service life. |

|

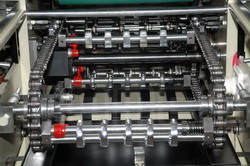

Printing Cylinders We have a three cylinder design. All the cylinders have cast iron bodies with a numbers of ribs. And are all hard chrome plated. The plate and blanket cylinders are fitted with contact bearers, giving them increased rigidity. All the printing cylinders have helical drive gears. |

|

Aluminium Runners Preset Digital Repeat Controller Electronic No Sheet Detector |